QuoteCQ users can download the material exceptions in an excel file to handle offline

- In the Material Costing tab, navigate to the Actions button and select Reports.

- The Print Report screen will pop-up. In the Report option, select "Exceptions".

- In the Sub Category Report, users will find different export options:

- Excess: it downloads the lines whose selected supplier option has an Order Qty higher than the Requested Qty, resulting in excess material.

- At Risk: it downloads the lines which were marked at risk in the Material Costing Review tab.

- No Bid: it downloads the lines marked as no bid in the Material Costing tab.

- Alternate Parts: it downloads the lines where any of the MPNs was added as an alternate to the original line, after uploading the BOM.

- Exception Report: it downloads an excel file gathering all kind of exceptions.

Exceptions and definitions

- Parts Not Installed - list of parts marked as Do Not Install on the BOM tab that the end customer wants the CM to purchase, but the CM will not actually install that part. These won't contribute to the driver count toward costing labor activities, but it would count toward the material subtotal in the final quote.

-

Pending Alternates - list of lines that have alternates that have not been approved. An alternates approval webpage link for suppliers can be generated from the Material Costing tab.

-

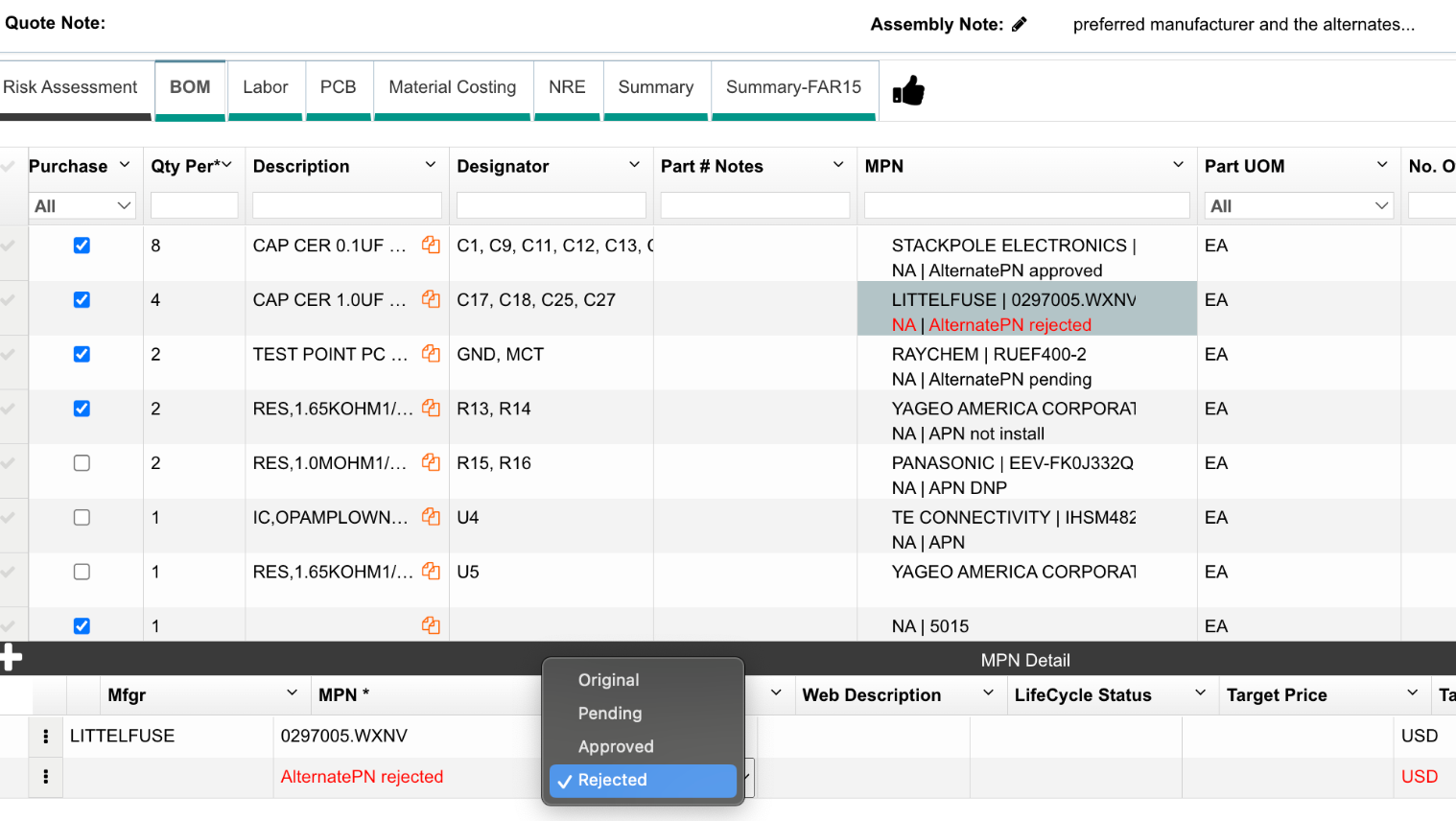

Approved Alternates - alternates that the end customer or the CQ user has approved. Alternates can be marked as Approved from the BOM tab by clicking on the MPN and editing the status like shown below.

-

Rejected Alternates - list of alternates that were rejected whether internally or by the end customer.

-

No Bid - list of parts that the CQ user has chosen to no-bid so that they are not reflected in the final unit price. You can No Bid lines on the Material Costing tab by selecting lines, then clicking Edit > No Bid.

-

Lead Time Risk - list of parts that have longer lead times

-

Material At Risk - any line items that the CQ user has flagged as a risk in the system will show up in this section. Mark lines as at risk from the Material Costing tab.

-

Cross Match - list of line items where the CQ user selected an MPN that was not an exact match to the MPN on the BOM. In other words: the part did not have a Cross Score of Exact. For example, buying a part with a slightly different packaging where there is a slight MPN difference.